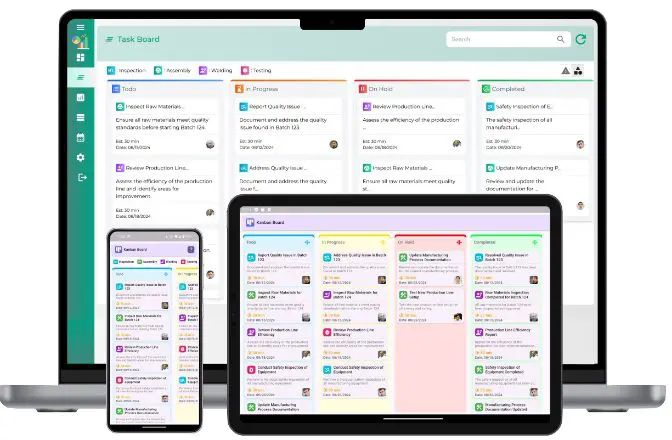

Our entire production line is built upon the principles of Kanban & Kaizen which allow the creation of products with an emphasis on Continuous Improvement & Just In Time (JIT) production.

Kanban: A lean manufacturing technique that helps optimize production and minimize waste through visualizing workflow and inventory control.

Kaizen: A continuous improvement approach that focuses on making incremental changes to the manufacturing process to enhance efficiency and quality.

Optimised production through a visualised workflow

Continuous improvement & enhance efficiency

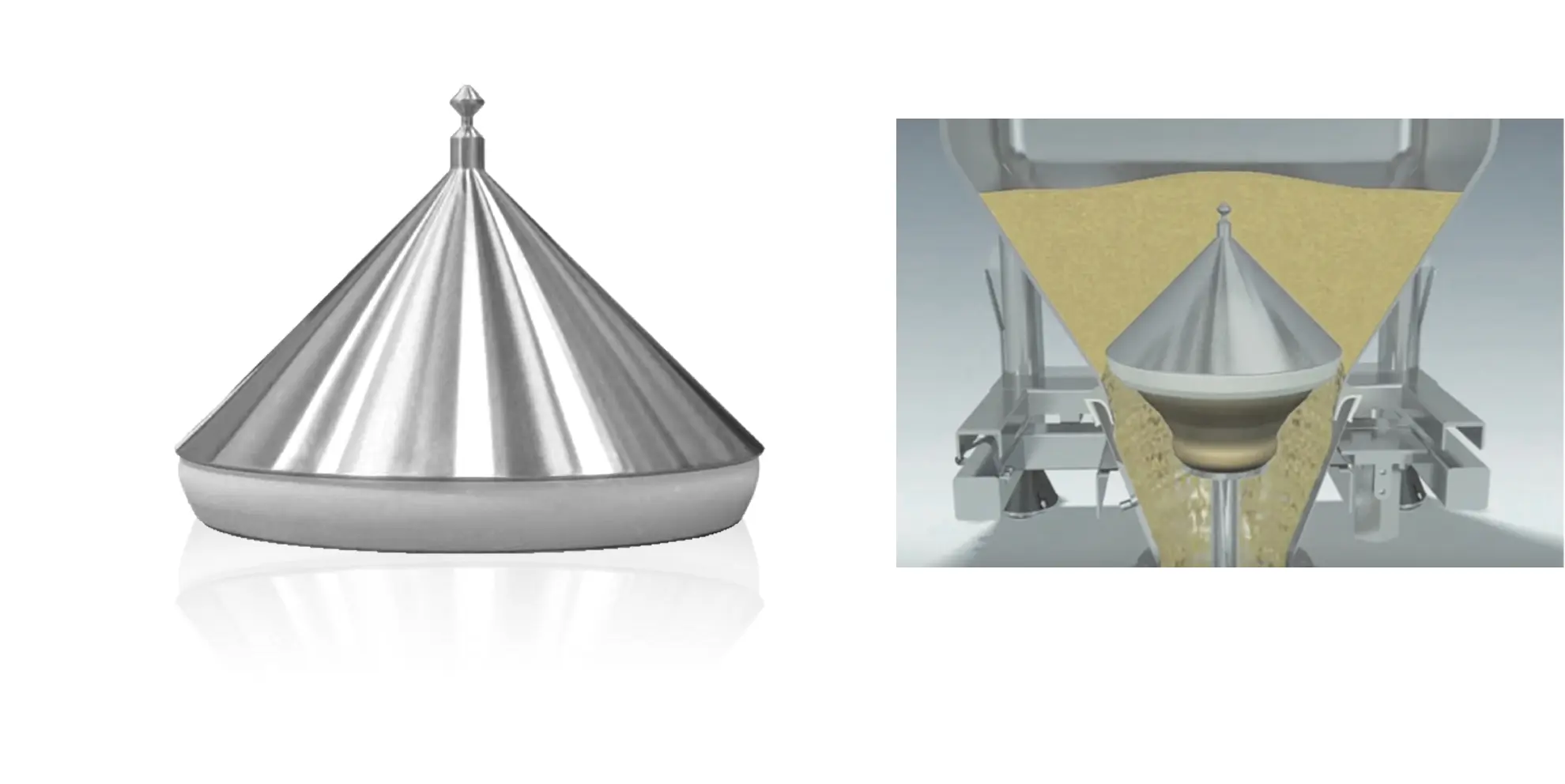

We adopt a lean process flow with gravitational dosing of ingredients.

Ingredients are dosed from the upper floor into the Matcon IBC Bin (UK) below. After blending, they are discharged via gravity directly into the High-Speed Topack (Japan) packing machines on the lower level.

We adopt a lean process flow with gravitational dosing of ingredients.

Ingredients are dosed from the upper floor into the Matcon IBC Bin (UK) below. After blending, they are discharged via gravity directly into the High-Speed Topack (Japan) packing machines on the lower level.

AVOIDING

POWER - HANDLING ISSUES

PROVIDING A CONSISTENT

FLOW FOR EACH PRODUCT

Solve & prevent poor flow that is caused by power bridging.

Ratholing can lead to costly power flow problems.

Ensure hygiene, safety & prevent cross-contamination.

Eliminate powder mix segregation to ensure consistent mass flow.

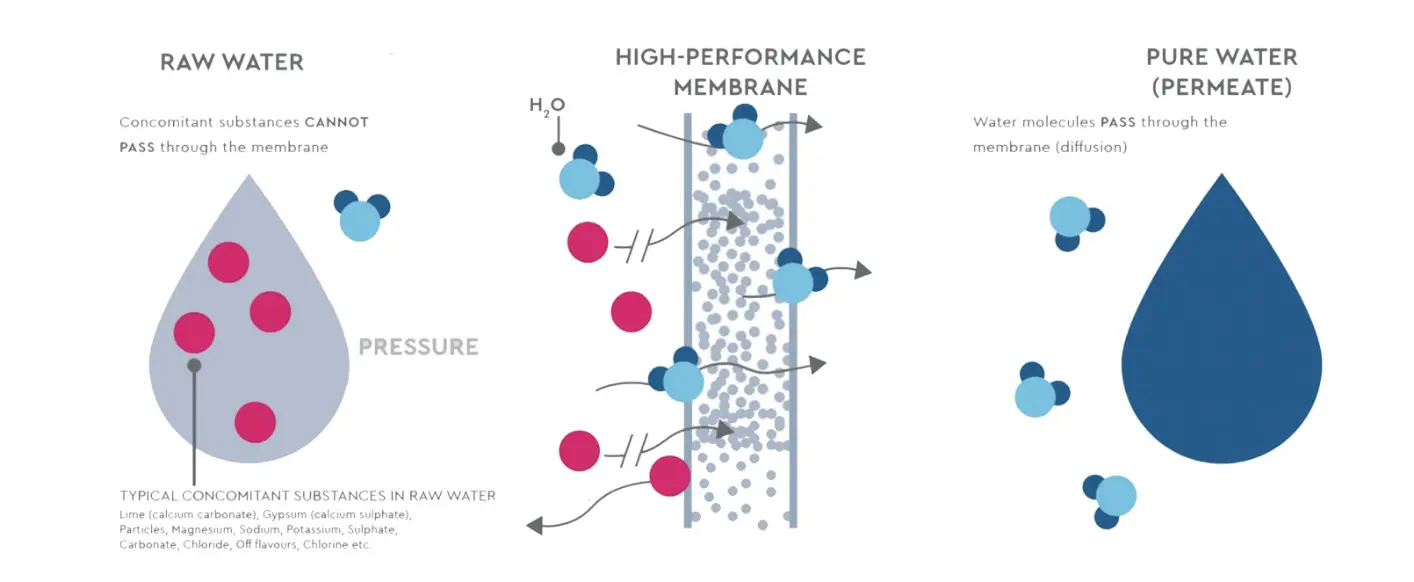

Traditionally used in the pharmaceutical industry, we adopt a RO-EDI system. Our purified water is free from impurities & removes the need for any preservatives.

This purified water is used in our production of liquid chlorophyll, mixing of supplement and blending for personal & homecare products.

Are you sure you want to

delete this 1 Item?