Utilizing Data To Maximise Manufacturing Efficiency

Advanced Tech Allows Teams To Focus On Higher-Value Activities

Streamlining Operations For Optimal Efficacy

Unleashing The Power Of Innovation Through Technology

Responsive Action To Prevent

Downtime & Improve Overall Efficiency

Optimize The Supply Chain- Managing

Inventory Levels & Improving Overall Logistics

Interconnected Devices And Systems Help

In Making Informed Strategic Choices.

Data Helps To Predict Equipment Failures And Maintenance Needs, Enabling Proactive Measures To Reduce Downtime And Extend Machinery Lifespan.

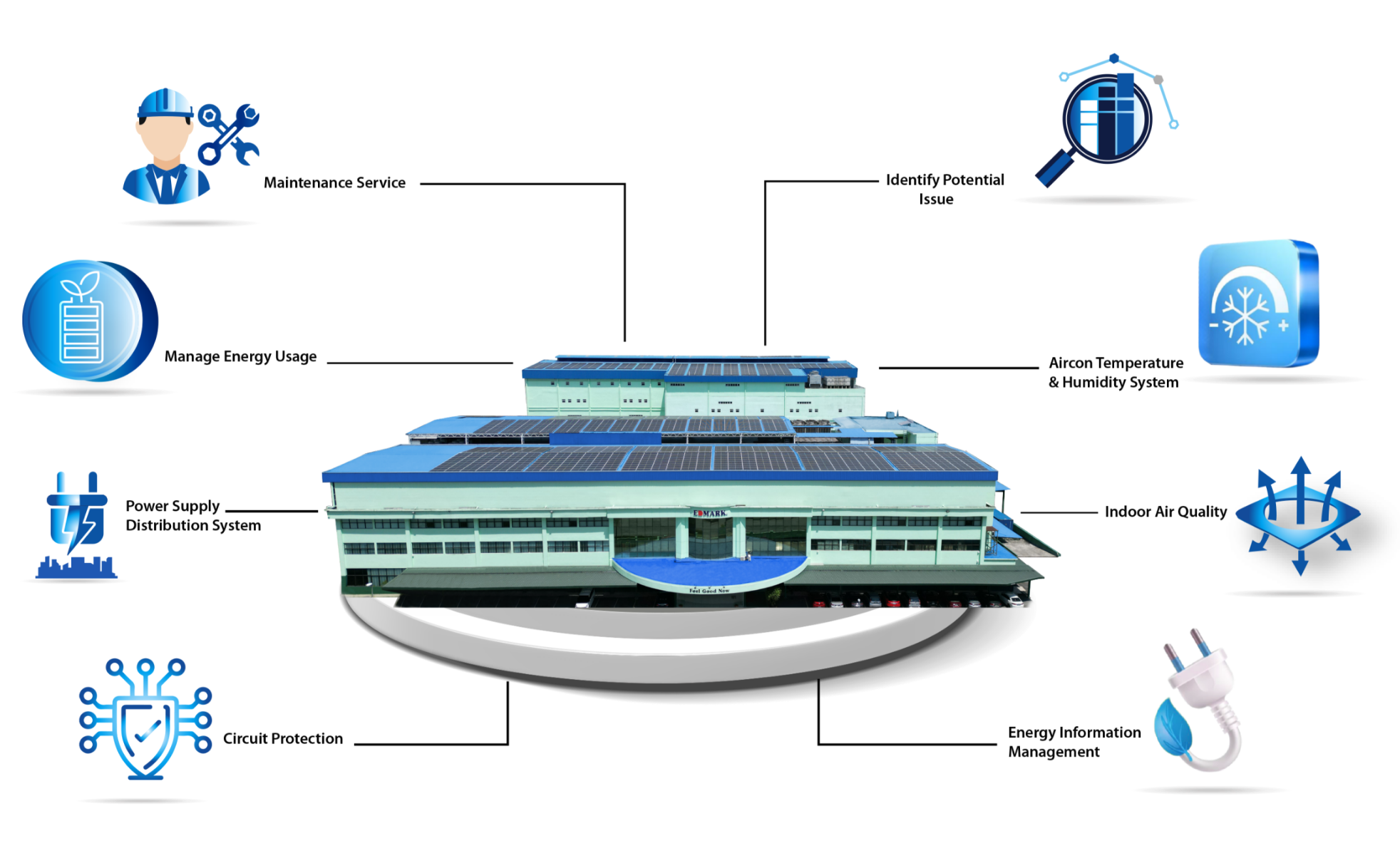

Building Management System

Building Management System

Monitor, Control & Automate Key Building Systems To Enhance The Overall Efficiency & Provide A Comfortable & Sustainable Environment In Line With ESG

Centralize Control And Monitor Various Building Components Temperature & Humidity

Maintains A Comfortable, Controlled Temperature With Energy-Saving Features

Energy Efficiency & Creating A Comfortable And Well-Lit Environment For Overall Operations

Regulate Indoor Air Quality To Meet Our GMP, ISO 22000 Food Safety Standards

Are you sure you want to

delete this 1 Item?